Golf club acoustics are an increasingly technical aspect of club design. Designers from golf’s top brands tell us why … and reveal how they create that satisfying impact sound.

“We do a lot of work on iron sound through the rear cavities,” adds Jertson. “We can make the face thin because the 17-4 steel we use is durable. Then to fine-tune the sound we use badges that we bond right up to the face.

“On the back of our G25 iron you’ll see a badge that is bonded on using vibration-dampening tape. The badge itself is an aluminium and elastomer material that dampens out a lot of the vibration. It looks like a decorative graphic, but that badge and custom tuning port really help the iron sound and feel very soft and solid.”

But when it comes to engineering the sound of irons, Mizuno believes what’s going on metallurgically is just as important as the head design itself – and that is why the company favours forging its steel – bending and compressing the hot metal – as opposed to casting, in which liquid metal is poured into a mold. “With any forged iron, the geometry of the head has traditionally been either muscleback or shallow cavity,” says Llewellyn. “Plus the mild carbon steel we use is not as strong as stainless, so the faces tend to be thicker. You can imagine a forged head is very rigid, and that lends itself to a more solid sound and feel.”

But Mizuno also believes its patented grain-flow forging technology, as found in all MP irons and the game-improver JPX 825 Pro, gives it the edge even on other forgings. “If you slice the head in half and look at it through a microscope you can see the metal has grains, which flow in one predominant direction,” adds Llewellyn. “The nature of that is that the head vibrates longer. This means the golfer can feel the ball on the face for a split second longer.”

Dialling tone

Over the past decade or so acoustic engineering has exploded – and not just in golf. Car builders now research what is reckoned to be the most luxurious door-closing ‘thunk’, and ape it in their new models. There are even reports of a company wanting to optimise the sound of its cheese crackers so they have the proper, quality snap when broken in two.

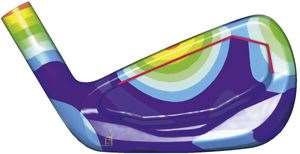

Essentially, the roots of this sound surge can be traced to new and incredibly sophisticated computer software. Computer Aided Design and Engineering allows golf club designers to actually simulate impact on a computer screen and assess and alter the sound a club makes at impact. Similar to how Tour pros dial in their launch angles and spin rates on launch monitors, today’s club engineer can program pitch, volume and duration of a clubhead before the metal to build it is even ordered. Instead of creating 50 clubs – or 50 car doors – for testing, you only have to build one.

“We do all our work at the front end, basically doing simulations on our virtual golf clubs in the CAD world,” says Mizuno’s Llewellyn. “We can apply an impulse to the clubface and actually see specific parts of the head vibrating.”

“We have programs that simulate a club hitting a ball and measure the sound profile,” adds Callaway’s Gibbs. “It looks at sound pressure waves created by impact. We extract their characteristics and go through a procedure to optimise geometry and mass to make the sound as pleasing as possible.”

Related Articles

Callaway Expands Quantum Range with Fairway Woods, Hybrids and Irons

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

.jpg&h=172&w=306&c=1&s=1)

Mizuno Expands Pro Line-Up with All-New Modern Series: M-13 and M-15

Latest News

Cameron John ticks Vic Open off bucket list

Lydia Hall completes Vic Open triumph

Big guns slip up as Spaniard Elvira lifts Dubai crown

Most Read

FootJoy Introduces All-New FJ Pulse for 2026

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

PING G440 K: Straightest, Most Forgiving Driver PING Has Ever Built

.jpg&h=115&w=225&c=1&s=1)