Golf club acoustics are an increasingly technical aspect of club design. Designers from golf’s top brands tell us why … and reveal how they create that satisfying impact sound.

Words: Duncan Lennard Photography: Ping; TaylorMade; Mizuno; Callaway

Golf’s most famous-sounding golf club gave its tone to an entire company. When struck from its enlarged sweetspot, Karsten Solheim’s 1959 A1 putter gave a mellow mid-pitched ring, not unlike a small bell or a musical triangle, thanks to its so-called sound slot. It’s a hard tone to put into words, but suffice to say Lee Westwood could quite easily be walking around today with a large DING or even TING on the side of his bag.

Solheim was one of the first golf club engineers truly to embrace the importance of impact sound. He appreciated that sound is our second-most immediate way of telling how much we like a club, behind visual appeal. He used it to give feedback on the shot – if you didn’t get the right ding, you had mishit the ball. He even used it in his early marketing, creating ad campaigns that featured the sound.

But above all, he recognised the intimate and consummate relationship between sound and feel. “With a putter, probably 90 percent of its feel is down to the sound it makes,” claims Ping’s senior design engineer Marty Jertson.

“We’ve done tests with golfers wearing noise-cancelling headphones. They hit a putter that made a ding like the A1, one that made no sound at all, and one that made a normal modern medium sound. Without hearing impact, they could not tell any difference in feel.

“It’s a perception thing. When a club sounds muffled or quiet, we perceive the face as feeling soft and the ball coming off the face slower – even if it isn’t. When a club sounds louder or harder, we feel the face as hotter or more powerful.”

Perception it may be, but sound’s influence is no less profound. In 2001, Callaway launched the Big Bertha C4 driver. Despite an advanced design and competitive performance, the dull impact from its carbon composite head gave it the impression of being powerless and dead – especially when set against the fiery cracks of the burgeoning titanium market. Callaway phased the club out within two years. Apparently, when it comes to golf clubs, hearing is believing.

With a range of vibration and dampening properties, multi-material clubs such as Callaway’s FT Optiforce present a sound challenge for modern designers.

With a range of vibration and dampening properties, multi-material clubs such as Callaway’s FT Optiforce present a sound challenge for modern designers.The sound of violence

Given the range of shots needed on the golf course, it’s no surprise today’s club engineers are looking to design different sound characteristics into different clubs. Drivers, naturally, need to sound hot-faced, powerful. “Powerful but not painful,” is how Jertson describes it.

Driver clubhead acoustics have become increasingly complex as driver design has got increasingly sophisticated. “It was when we started looking at bigger volumes, thinner walls, multi-materials, adjustability and non-traditional shapes that sound differences emerged,” says Evan Gibbs, senior manager of product performance at Callaway. “It became a challenge to incorporate those elements while retaining a pleasing sound.”

Gibbs believes those early trials with trying to make composite material sound more metallic has enabled Callaway to gain expertise in acoustic analysis. “We control sound by controlling the stiffness and the mass of the head,” he reveals. “We generally use head shape, or geometry, to control the stiffness, though we can also add design elements such as internal ribs to stiffen up specific areas. We control mass largely through the head’s wall thickness.”

Callaway’s Forged Composite crown, as found in its new FT Optiforce driver, presents its own sound challenges for Gibbs and his team. “Forged Composite has a different stiffness and mass than titanium or steel, and also dampening characteristics different from metal. When you introduce multi-materials that all behave differently it makes it more complicated, though ultimately more beneficial.”

For TaylorMade, many driver sound issues are based around adjustability. The R1 driver, their most adjustable model to date, features a loft adjustment sleeve, an adjustable sole plate and weight ports.

The inside of the TaylorMade R1 reveals ribs, carefully positioned to stiffen areas prone to unwanted vibration.

The inside of the TaylorMade R1 reveals ribs, carefully positioned to stiffen areas prone to unwanted vibration.“They create a big sound challenge because we need to free up weight to incorporate these mechanisms, and that means making the walls very thin – just 0.45mm on the crown,” says TaylorMade VP of R&D for metal woods Todd Beach. “And when the walls get thin, the club gets loud.

“These mechanisms also change the way the head vibrates. We have different parts vibrating at different frequencies, and each affects the overall sound of the club. So we need to add internal ribs, mainly on the sole to support the adjustable sole plate, and to tie into the weight ports. They stabilise the structure so it vibrates at the target frequency.”

The R1 has a further sound trick up its sleeve – polyurethane foam inside its sole plate. “It’s called a constrained layer, essentially a soft bit between two hard ones to calm vibration,” adds Beach. “It helps us engineer the right duration of impact noise.”

While computers create sound, it is trialled in the real world. Here, Ping mics up a mannequin to capture impact feedback.

While computers create sound, it is trialled in the real world. Here, Ping mics up a mannequin to capture impact feedback.Strident trident

The duration of impact sound is one of three areas golf club engineers target when manipulating impact sound. The others are amplitude or loudness, and frequency or pitch.

“For frequency, imagine a string being plucked,” explains Mizuno’s US head of R&D David Llewellyn. “It will vibrate in several different modes. The first would be the entire string bouncing up and down. Then there are ripples along the string, and then ripples along the ripples. The golf clubhead vibrates in the same way. There are actually an infinite number of vibration modes, but only the first few contribute much to the sound. By focusing on those important modes we can adjust the head geometry to get the head frequencies we want.”

F or the driver, typical frequencies are 2,500-5,000Hz – though it’s not quite as simple as that. As Beach says, different parts of the clubhead vibrate at different frequencies, so the ultimate sound the club makes is actually more of a chord than a note. According to Llewellyn, a difference of 1,000Hz in that tone can mean a club that sounds sweet, and one that sounds cracked.

or the driver, typical frequencies are 2,500-5,000Hz – though it’s not quite as simple as that. As Beach says, different parts of the clubhead vibrate at different frequencies, so the ultimate sound the club makes is actually more of a chord than a note. According to Llewellyn, a difference of 1,000Hz in that tone can mean a club that sounds sweet, and one that sounds cracked.

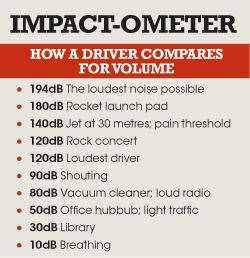

Typical driver amplitudes range from 98-118 decibels – that’s compared to a hand drill at 98dB and a rock concert at 115dB. “You will generally find that drivers designed for lower ball speeds are engineered to produce louder sounds,” adds Ping’s Jertson. “Stronger players, the guys on Tour, hit the ball harder, so generate a louder sound anyway.

“We would mostly engineer this through geometry. Sharper corners reverberate at harsher frequencies, while smooth, rounded shapes give more muted sounds. Our G25 model, a driver that can be used by all standards, has a larger footprint and its crown is flatter, which boosts forgiveness while naturally giving a bit more of a powerful sound. The i20, geared towards the higher swing-speed golfer, has a more rounded shape and gives a slightly more muted sound.”

As for duration, the target length of sound is again a Goldilocks affair – not too long, not too short. “Currently, for duration we strive to damp down 95 percent of the amplitude between a range from 50 to 120 milliseconds,” says Jertson. “Less than 50 milliseconds can be perceived as too short and piercing, and more than around 120-150 milliseconds is perceived to ring out for too long.

“A typical driver impact lasts around 450 microseconds – so its impact sound lasts more than 10 times as long as the actual impact itself.”

Silver tone

While driver acoustics are naturally concerned with perceptions of power, things get a little less clear with irons.

While the longer irons – such as they exist in the era of the hybrid – are built for distance and forgiveness, and favour a more powerful sound, short irons and wedges are all about feel and control, and need to sound softer. How does one set achieve both?

“To some extent it happens naturally through face thickness,” explains Ping’s Jertson. “Take our i20. The 4-iron has a thinner face to make it more flexible and more powerful. A thinner face naturally creates a more powerful sound.

“With wedges, we want the perception that the ball comes off softer. These clubs don’t need power and forgiveness design elements, and feature the thicker face that stabilises the head and gives better distance control.

It also makes impact sound more solid, softer, quieter.”

Despite this, iron designers are still presented with a problem. Thin and flexible clubfaces are great for power and forgiveness but tend to produce harsher, less pleasing sounds.

“We do a lot of work on iron sound through the rear cavities,” adds Jertson. “We can make the face thin because the 17-4 steel we use is durable. Then to fine-tune the sound we use badges that we bond right up to the face.

“On the back of our G25 iron you’ll see a badge that is bonded on using vibration-dampening tape. The badge itself is an aluminium and elastomer material that dampens out a lot of the vibration. It looks like a decorative graphic, but that badge and custom tuning port really help the iron sound and feel very soft and solid.”

But when it comes to engineering the sound of irons, Mizuno believes what’s going on metallurgically is just as important as the head design itself – and that is why the company favours forging its steel – bending and compressing the hot metal – as opposed to casting, in which liquid metal is poured into a mold. “With any forged iron, the geometry of the head has traditionally been either muscleback or shallow cavity,” says Llewellyn. “Plus the mild carbon steel we use is not as strong as stainless, so the faces tend to be thicker. You can imagine a forged head is very rigid, and that lends itself to a more solid sound and feel.”

But Mizuno also believes its patented grain-flow forging technology, as found in all MP irons and the game-improver JPX 825 Pro, gives it the edge even on other forgings. “If you slice the head in half and look at it through a microscope you can see the metal has grains, which flow in one predominant direction,” adds Llewellyn. “The nature of that is that the head vibrates longer. This means the golfer can feel the ball on the face for a split second longer.”

Dialling tone

Over the past decade or so acoustic engineering has exploded – and not just in golf. Car builders now research what is reckoned to be the most luxurious door-closing ‘thunk’, and ape it in their new models. There are even reports of a company wanting to optimise the sound of its cheese crackers so they have the proper, quality snap when broken in two.

Essentially, the roots of this sound surge can be traced to new and incredibly sophisticated computer software. Computer Aided Design and Engineering allows golf club designers to actually simulate impact on a computer screen and assess and alter the sound a club makes at impact. Similar to how Tour pros dial in their launch angles and spin rates on launch monitors, today’s club engineer can program pitch, volume and duration of a clubhead before the metal to build it is even ordered. Instead of creating 50 clubs – or 50 car doors – for testing, you only have to build one.

“We do all our work at the front end, basically doing simulations on our virtual golf clubs in the CAD world,” says Mizuno’s Llewellyn. “We can apply an impulse to the clubface and actually see specific parts of the head vibrating.”

“We have programs that simulate a club hitting a ball and measure the sound profile,” adds Callaway’s Gibbs. “It looks at sound pressure waves created by impact. We extract their characteristics and go through a procedure to optimise geometry and mass to make the sound as pleasing as possible.”

At TaylorMade, this software helps engineers come up with the rib configuration needed to control vibration from its R1 driver’s adjustability mechanisms. “Rib configuration is an involved process for our engineers,” says Beach.

“Fortunately we have an optimisation tool on the computer that will search hundreds of different rib configurations to find the one that will hit our target frequencies with the minimal weight.”

While impact sounds can be dialled in by computer, companies naturally test acoustics in the real world, after a club has gone into production. At Callaway, clubheads are placed in a small room called an anechoic chamber – a very sterile, echo-less environment – and struck with a mallet.

Meanwhile Ping use something called a Binaural Head. “We put a mannequin head at the exact height and distance from the ball but on the left side of the impact,” says Jertson. “We record impact from its perspective. The important thing here is that we measure the sound almost exactly as how the player hears it – not in a lab setting or environment.”

Face value

As for putters, as Marty Jertson has asserted, 90 percent of their feel is down to sound. Face inserts, then, are designed not so much for feel as for the sound they create, along with the roll-enhancing technologies of the design.

“In the past 10 years or so the ball has got firmer,” says Jertson. “So we have had to do things in the putter to make it seem the ball is not coming off the face too hot. Our Nome TR and Scottsdale TR models use an aluminium insert with True Roll grooves, which help make ball velocity consistent across the face. The grooves dissipate some of the energy, and they combine with the aluminium to create a desirable sound with the modern ball. That’s the big thing in putters; not too soft, not too hot, right in between.”

It’s a theme that comes up time and again with golf club acoustics. When it comes to defining that pleasing sound, no one can tell you what it is, but everyone can tell you what it isn’t.

“It’s hard to say what a great sound is,” says Callaway’s Gibbs. “We’ve captured the sound profiles of dozens of clubs and canvassed opinion on them, and we’ve found there is a threshold of acceptability. We may not be able to pin down one perfect sound, but we can certainly predict with accuracy what is too harsh, and what is too dead.”

But perhaps the most intriguing aspect of golf club acoustics is that companies devote so much time and energy to an aspect that has almost zero effect on the club’s performance. Sound doesn’t affect the club’s power, or its ability to apply spin, or even its forgiveness – other than via feedback on mis-strikes. It merely affects our perception of those things.

The reason they do, of course, is a simple one; if a club sounds bad, we won’t buy it. “We could come out with a driver that gave the golfer 20 extra yards,” Jertson concludes. “But if it sounded like it still had the headcover on, it would flop.”

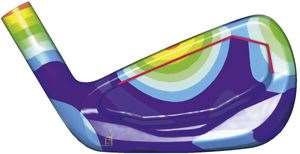

Designers balance harsh sounds created by thin, powerful faces by stiffening parts of the head’s perimeter, as in Mizuno’s JPX 825.

Designers balance harsh sounds created by thin, powerful faces by stiffening parts of the head’s perimeter, as in Mizuno’s JPX 825.Good – and bad – vibrations

While the sole of every iron is generally solid and rarely causes unwanted vibration and noise, things are different in the upper and high-toe regions of the face. “These zones are thinner, and naturally attract more vibration,” says Mizuno’s David Llewellyn.

“This is why our new JPX models feature a subtle angled brace out on high toe to add rigidity to these weaker zones. The pocket cavity used in the JPX 825 Pro and the MP 53 is a weight-saving strategy, allowing us to add these braces without adding extra mass to the clubhead.”

Golf’s changing soundtrack - Todd Beach TaylorMade VP of R&D, metal woods

“We might think of a pleasing impact sound as a constant; but like gear itself, it has its own trends. Sound definitely migrates over time.

“Back in 1979, when our first steel-headed woods came out, we were having to put foam in the head to dampen the sound because people liked the sound of persimmon. In fact the sound of the driver was the only really problem the Tour pros had with those early metal woods.

“But when titanium came out – we launched the Ti Bubble 2 in 1996 – heads got bigger. In fact at 285cc, the Ti Bubble 2 practically doubled previous head sizes. Suddenly, the amount of foam we were having to use began to affect the performance of the club, so we took it out. Sure, the club sounded louder, but people began to associate that louder sound with the performance benefits of titanium – so it became accepted. In a few short years, the ‘pleasing’ driver sound changed dramatically.”

Related Articles

Callaway Expands Quantum Range with Fairway Woods, Hybrids and Irons

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

.jpg&h=172&w=306&c=1&s=1)

Mizuno Expands Pro Line-Up with All-New Modern Series: M-13 and M-15

Latest News

Cameron John ticks Vic Open off bucket list

Lydia Hall completes Vic Open triumph

Big guns slip up as Spaniard Elvira lifts Dubai crown

Most Read

FootJoy Introduces All-New FJ Pulse for 2026

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

PING G440 K: Straightest, Most Forgiving Driver PING Has Ever Built

.jpg&h=115&w=225&c=1&s=1)