Golf club acoustics are an increasingly technical aspect of club design. Designers from golf’s top brands tell us why … and reveal how they create that satisfying impact sound.

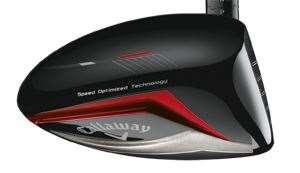

With a range of vibration and dampening properties, multi-material clubs such as Callaway’s FT Optiforce present a sound challenge for modern designers.

With a range of vibration and dampening properties, multi-material clubs such as Callaway’s FT Optiforce present a sound challenge for modern designers.The sound of violence

Given the range of shots needed on the golf course, it’s no surprise today’s club engineers are looking to design different sound characteristics into different clubs. Drivers, naturally, need to sound hot-faced, powerful. “Powerful but not painful,” is how Jertson describes it.

Driver clubhead acoustics have become increasingly complex as driver design has got increasingly sophisticated. “It was when we started looking at bigger volumes, thinner walls, multi-materials, adjustability and non-traditional shapes that sound differences emerged,” says Evan Gibbs, senior manager of product performance at Callaway. “It became a challenge to incorporate those elements while retaining a pleasing sound.”

Gibbs believes those early trials with trying to make composite material sound more metallic has enabled Callaway to gain expertise in acoustic analysis. “We control sound by controlling the stiffness and the mass of the head,” he reveals. “We generally use head shape, or geometry, to control the stiffness, though we can also add design elements such as internal ribs to stiffen up specific areas. We control mass largely through the head’s wall thickness.”

Callaway’s Forged Composite crown, as found in its new FT Optiforce driver, presents its own sound challenges for Gibbs and his team. “Forged Composite has a different stiffness and mass than titanium or steel, and also dampening characteristics different from metal. When you introduce multi-materials that all behave differently it makes it more complicated, though ultimately more beneficial.”

For TaylorMade, many driver sound issues are based around adjustability. The R1 driver, their most adjustable model to date, features a loft adjustment sleeve, an adjustable sole plate and weight ports.

The inside of the TaylorMade R1 reveals ribs, carefully positioned to stiffen areas prone to unwanted vibration.

The inside of the TaylorMade R1 reveals ribs, carefully positioned to stiffen areas prone to unwanted vibration.“They create a big sound challenge because we need to free up weight to incorporate these mechanisms, and that means making the walls very thin – just 0.45mm on the crown,” says TaylorMade VP of R&D for metal woods Todd Beach. “And when the walls get thin, the club gets loud.

“These mechanisms also change the way the head vibrates. We have different parts vibrating at different frequencies, and each affects the overall sound of the club. So we need to add internal ribs, mainly on the sole to support the adjustable sole plate, and to tie into the weight ports. They stabilise the structure so it vibrates at the target frequency.”

The R1 has a further sound trick up its sleeve – polyurethane foam inside its sole plate. “It’s called a constrained layer, essentially a soft bit between two hard ones to calm vibration,” adds Beach. “It helps us engineer the right duration of impact noise.”

Related Articles

Callaway Expands Quantum Range with Fairway Woods, Hybrids and Irons

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

.jpg&h=172&w=306&c=1&s=1)

Mizuno Expands Pro Line-Up with All-New Modern Series: M-13 and M-15

Latest News

Cameron John ticks Vic Open off bucket list

Lydia Hall completes Vic Open triumph

Big guns slip up as Spaniard Elvira lifts Dubai crown

Most Read

FootJoy Introduces All-New FJ Pulse for 2026

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

PING G440 K: Straightest, Most Forgiving Driver PING Has Ever Built

.jpg&h=115&w=225&c=1&s=1)