80 years of experience, four manufacturing plants and 40,000 testers; just three of the things it takes for Titleist to produce ...

The chances are if you’re a committed golfer, at some stage in your golfing life you’ll have put a Titleist ball into play.

It’s been 13 years since the iconic Pro V1 range was launched, and it’s 80 years since the company was founded. But had it not been for an X-ray machine in a dentist’s surgery things could have worked out very differently, as director of Titleist Golf Ball Product Management Michael Mahoney explained.

Acushnet has more than 900 active US golf ball patents; each ball goes through rigorous testing; a fine layer of paint is applied.

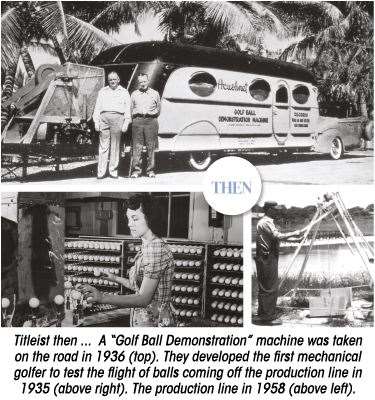

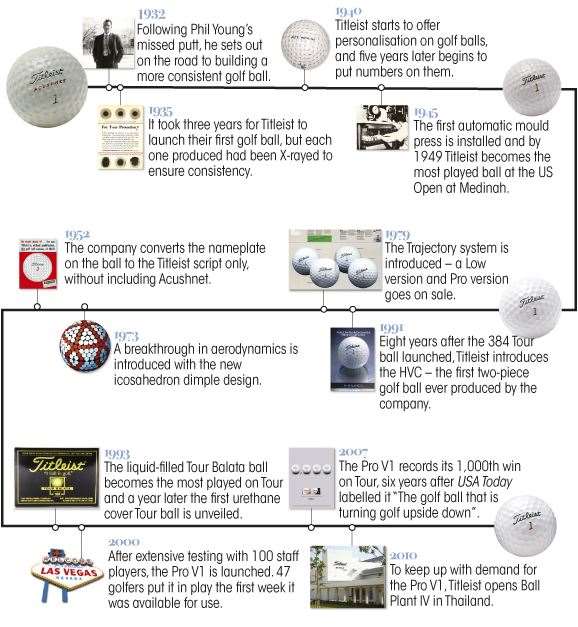

Acushnet has more than 900 active US golf ball patents; each ball goes through rigorous testing; a fine layer of paint is applied.In 1932, avid golfer Phil Young was out playing in New Bedford and on the 18th hole he had a relatively short putt to win his match. He stroked it pure, but the ball missed outside the hole, even though he was convinced he’d put a good stroke on the ball – if there was no way it could have been the golfer, it had to be the golf ball. He was given a hard time by his partners for that, but he was curious, so he asked a dentist friend if he could use his X-ray machine.

“He X-rayed the ball he missed the putt with and found that the core wasn’t round – it was off centre and the ball rolled impurely as a result of a product that wasn’t consistent. He felt he could do it better and he could make products better and more consistent, and he spent three years working on that process.”

Titleist may have started out small, but it’s grown to be the dominant ball brand in the market today. And while lots of things have changed in the 80 years since, Mahoney is adamant that certain values still remain.

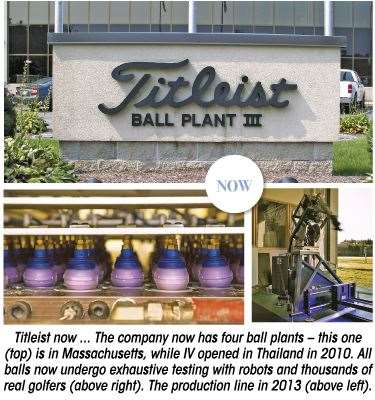

“Part of our identity has to do with how we haven’t changed and what our core values are. We started out as a process company, we continue today to be a process company. When the company was set up it was really about looking at how to make a better, more consistent golf ball. To this day we spend so much time and attention on the process – be that the process of development or the process of making golf balls. The scale has obviously changed dramatically – we make 25 million dozen golf balls a year now – but the attention to detail has remained constant.”

Titleist’s pursuit of excellence involves extensive testing, research and development, but in an age when the likes of Srixon, TaylorMade, Callaway and Nike all have their piece of the market, what sets Titleist’s processes aside from that of its rivals? “I think the fact that we have our own proprietary technology that we have developed. There are certain elements to it that are common for any golf ball manufacturing, but to a large degree what you see was designed and built in our own manufacturing facilities by our associates, and that’s becoming more and more rare these days. So the fact that we control the processes is a significant advantage,” adds Mahoney.

“Our level of quality check that exists throughout the process is unprecedented – and there are many, many steps in making a golf ball. We take samples from the very first stage and test it to make sure it meets our performance specifications. The testing criteria we set up for any product really happens throughout the process, whether it be core moulding to adding the casing layer, putting the urethane cover on, to the paint process, to the stamping – there are quality checks every step of the way and that results in a very consistent product coming off the line.” We’ve been told that even a slightly lighter imprint on the “T” in the logo is enough to reject a ball.

“Our level of quality check that exists throughout the process is unprecedented – and there are many, many steps in making a golf ball. We take samples from the very first stage and test it to make sure it meets our performance specifications. The testing criteria we set up for any product really happens throughout the process, whether it be core moulding to adding the casing layer, putting the urethane cover on, to the paint process, to the stamping – there are quality checks every step of the way and that results in a very consistent product coming off the line.” We’ve been told that even a slightly lighter imprint on the “T” in the logo is enough to reject a ball.

And it’s not just Titleist balls that get the testing treatment, either. “We run more tests on golf balls than any other manufacturer and it’s probably more than all the others combined,” says Mahoney. “The companies that make the robot testing devices we use tell us we wear out parts that they wouldn’t see worn out in other places.”

On the production line, the material for the core begins as a slab of rubber which is fed into something resembling a pasta-maker. The result is a long sheet, which is left to cool for up to ten hours before being sliced into long, thin strips. The strips are cut into smaller pieces, which are placed into a mould that shapes the core. The cover is then attached in two pieces, which are spot-welded together, before the whole thing is placed in a dimpled mould and turned into a sphere under heat and pressure. The ball is then buffed to erase a ridge left by the two halves before the logo and number are stamped on, and two spray guns apply a latex primer and finishing coat. All that, so anyone from an 18-handicapper or Adam Scott can trust their ball.

Titleist’s presence on Tour is, and always has been, impressive. In 2012, Pro V1s recorded 190 wins on worldwide tours, and as demand for the products grew in the brand’s formative years, Titleist hit on a novel way of making sure their reps were easy to spot. Mahoney told us: “Back when we started out on Tour, one of the things that was so important to our brand message – and this remains today – was that the ball you could buy in your golf shop was the same ball we were giving to pros, it was that good.

“We didn’t have a separate line we were making for tour players, so when an event would come into town we wanted to give players the opportunity to play that ball. They received a ‘chit’ to go into the golf shop and get four dozen free balls, which we would then replace. As popularity grew, and more players wanted to get that chit, spotting the Titleist representative was really important so the rep would start wearing a white coat on the range.”

It’s clear that Titleist holds its heritage dear, as well as maintaining the core values that helped them develop into a market leader.

It’s clear that Titleist holds its heritage dear, as well as maintaining the core values that helped them develop into a market leader.

Today’s balls are a world away from those that were played in 1932, but certain fundamentals remain. “It starts with the precision process in our founding,” says Mahoney, “and making every single ball consistently the same – cores that were centred, consistent dimple coverage. Eighty years ago, balls had very simple constructions. I think the introduction of aerodynamic changes in the 1970s to give different trajectories, and the fact we offered players those different trajectories, and they put them in play and utilised them for different types of shot, really influenced the one-ball rule. So the understanding of aerodynamics would be one of the key moments.”

Then there was the shift to different materials from a cover standpoint with the introduction of balata. “That generated a spin profile that would allow players to really improve their short game shots, which are ultimately the shots that help players to shoot better scores.

“That said, spin and those constructions meant a sacrifice on some distance so probably the most important golf ball innovation was the introduction of the Pro V1 in 2000, combining solid core construction which gives you outstanding distance with the urethane cover which allows you to generate the same sort of spin profile on short shots that you were getting on those balata constructions.”

The Pro V1 franchise has been one of the most-successful in golf history, but developing this revolutionary new technology had its challenges.

“The biggest change was when we shifted from wound to solid core construction,” said Mahoney. “Taking those winding machines out of the plant and moving towards moving big batches of solid core materials – that is the most significant change that we made in the past ten or 20 years.

“And in the past five to ten years, one of the changes to the process is how broadly we test with golfers. We’ve always tested a lot with golfers and with our Tour staff, but we’ve got to the point now that in the years leading up to a Pro V1 launch we have tested product with everyone in our Tour staff. We’ve been testing with literally everyone who’s played the Pro V1 or the Pro V1x. Beyond that, just in the US, we supply more than 40,000 golfers with prototype products to get feedback as we’re finalising the next generation of Titleist balls. We’ve done projects over several years where we’ve captured launch condition data throughout Asia, because we wanted to identify if there was anything different about an Asian golfer, or a Japanese golfer or a Korean golfer versus a European golfer, or an American golfer. That’s a big competitive advantage.”

Titleist is dominant in balls, but Mahoney knows the only way to stay at the top is to keep innovating. “It’s hard in the sense that we feel the balls are so good, the process to improve them gets a little bit harder every two years. But, the great thing about having such a large Tour staff, and having so many people play our golf ball, is that we get great feedback as soon as we launch a new product. As much as we can deliver a product that does what we want it to do, we really start finding out about the products after players put them into play and hitting shots when it really matters – that’s when we get great feedback from them. In 80 years the technology has changed dramatically, and our size and scale has changed dramatically, but our values haven’t. We remain very committed to the processes, to quality and to innovation.”

Titleist by numbers

24 - The number of men’s major championships won by Pro V1 or Pro V1x players since 2000.

65 - Including 2013, the number of consecutive years Titleist has been the No.1 ball at the US Open – the longest running equipment success story in golf.

750,000 - The approximate number of balls made per day at the company’s three wholly owned and operated manufacturing sites.

190 - The number of global Tour wins for Titleist’s Pro V1 and Pro V1x in 2012 – compared to 25 for the nearest rival.

352 - The number of spherically tiled tetrahedral dimples on the urethane cover of a Pro V1.

1,900 - The number of wins on worldwide tours with a Pro V1 since its introduction. A prototype version of the ball has been seeded on the world’s tours since last November.

How Tour players’ feedback helps - Michael Mahoney explains what happens.

“We get different types of feedback from different players. We would hesitate to say one is better than another because all golfers are different and we need to meet the demands of all of those types of golfer. A guy like Jason Dufner, who is really knowledgeable about the technology inside the product, will give us a lot of very specific feedback related to feel and spin characteristics. Adam Scott is another guy who is a feel-sensitive player. But then you go to a player like Rickie Fowler – he’s very flight-sensitive. He really has a great sense of trajectory, so he’s going to give you feedback related to the flight, as he’s not as feel sensitive. Zach Johnson is a guy we test with from an all-round standpoint – he’s got such a terrific

“We get different types of feedback from different players. We would hesitate to say one is better than another because all golfers are different and we need to meet the demands of all of those types of golfer. A guy like Jason Dufner, who is really knowledgeable about the technology inside the product, will give us a lot of very specific feedback related to feel and spin characteristics. Adam Scott is another guy who is a feel-sensitive player. But then you go to a player like Rickie Fowler – he’s very flight-sensitive. He really has a great sense of trajectory, so he’s going to give you feedback related to the flight, as he’s not as feel sensitive. Zach Johnson is a guy we test with from an all-round standpoint – he’s got such a terrific

short game, but really knows what his expectations are related to flight.”

Titleist’s milestones since 1932

Related Articles

New Release: Award-winning Wilson Staff model balls elevated for the elite

Callaway Expands Quantum Range with Fairway Woods, Hybrids and Irons

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

Latest News

Gotterup opens PGA Tour season by winning Sony Open

Review: Yering Meadows Golf Club

Callaway Expands Quantum Range with Fairway Woods, Hybrids and Irons

Most Read

FootJoy Introduces All-New FJ Pulse for 2026

Callaway Introduces Quantum Drivers, Powered by Revolutionary Tri-Force Face

PING G440 K: Straightest, Most Forgiving Driver PING Has Ever Built